Yamaha R1

Yamaha R1/YZF-R1 series model history timelines

The Yamaha YZF-R1, or R1, is an open class sport bike or Super bike, motorcycle manufactured by Yamaha Motor Company since 1998.

Yamaha

R1/YZF-R1 Model History Guide - How it all started

Yamaha R1/YZF-R1 series model history timelines

How it all started

It all started with a white sheet of paper at an informal meeting

in the paddock building at Killarney circuit near Capetown in South Africa.

The world’s best motorcycle journalists were just testing the newly launched

YZF1000R Thunder Ace. While the media was focused on this new Yamaha sportbike

in the hot and sunny South African environment, a group of Yamaha Japan’s

key engineers took the opportunity to discuss some new ideas with Yamaha’s

European product planners in this relaxed atmosphere.

Kunihiko Miwa, the man behind the R-series, had just been promoted project

leader of "a new supersport machine”. Mario Inumaru, senior product

planner and responsible for the whole European market, favoured the idea of

a really radical machine. His vision was to rejuvenate the race-bred supersport

class. Sales of race-oriented bikes had slowed down in the middle of the nineties,

but Europe was always a strong market for real supersport machines. The planners

in Yamaha Motor Europe’s office in Amsterdam believed in this segment,

and were more than happy to have an engineering team in Japan that supported

their ideas.No compromise

So while the world’s top motorcycle journalists were out testing the Thunderace, the little group of engineers and planners in the paddock building next to them were already thinking of their next, more extreme concept! Mr. Miwa told the planners that he had already started a design for a brand new 4 cylinder engine, and he wanted to integrate its chassis and engine into one unit in order to make this new bike the lightest and most compact in the class. He took his pencil and scribbled his basic technical idea on the white sheet of paper. The planners looked at it. Someone took a pen and added the words "NO COMPROMISE”. This later became the key concept for the whole development of R1. Miwa-san had a heavy burden put on his shoulders when they laid down the basic parameters: 150 HP, under 180 kg and handling like 600 cc sportbikes at that time!

New layout still valid today

Mr. Miwa and his team worked hard for about a year. Not much free time was left for sushi and sake. (for those not familiar with Japanese cuisine: these are raw fish and rice-wine). The basic layout the engineers came up with is still valid today, and it still sets the standards by which other supersport machines are judged:

- Ultra-short 4-cylinder engine with a triangular crankshaft and gearbox shaft layout

- Deltabox II chassis with the slant-block engine as stressed member to ensure high rigidity and low weight

- Ultra-long swingarm combined with a short wheelbase for superb handling together with excellent stability

- Rider position in the centre of the bike to ensure best weight distribution

Careful attention to details

Never has a high-volume production machine like the R1 received so much attention to even the smallest detail, and Mr. Miwa was soon called "Mr. No Compromise”.

Here are just some examples of his search for perfection: in order to make a straight shift linkage from the R1’s gear lever to the gearbox shaft, a hole was designed in the frame section over the swingarm pivot shaft. This innovative solution resulted in a better shift feeling, because of no bending moments on the shaft. The handlebars are bonded aluminium, and are 46% lighter than their welded counterparts. These are just two examples of how Yamaha’s attention to detail makes the R1 one of the most advanced supersport machines on the market.

R1 and R6: The top class supersport machines

R1 and R6 are Yamaha top class supersport machines. One could

think, the 600 cc is just a smaller version of the 1000 cc version. That's

wrong! Both bikes are entirely different!

Engine, chassis and riding style of both R1 and R6 are targeted for different

use. Kunihiko Miwa, the man behind R1 and R6 explains the differences.Without taking a closer look to Yamaha's 600 and 1000 supersports bikes, you may think they are pretty much the same. One is just a smaller version of the other one.

WRONG! Completely wrong....

Now you would straight away ask the question: Why does Yamaha not use common parts on both machines? It would certainly be cheaper and cost less development time. Kunihiko Miwa, who was responsible for both the R1 and the R6 as project leader, always shakes his head, when people bring up such subjects.

Says Miwa: "If you want to build a perfect supersport machine, you can not make faulty compromises. A 600 cc machine has to have a different character than a 1000cc bike. Naturally, weight, physical size and engine character will be different. If you try to use a 1000 chassis for example, you would automatically weaken certain advantages of a 600 cc."

Miwa goes on in his explanation:

"When we developed both bikes, our target was 'EXCITEMENT'.

Of course there are many variations of excitement for motorcycle riders. For supersport this certainly means hard riding and exploration of the bike's potential. The rider should be able to feel: When I do this or that, I can take the corner in the best possible way. I mean, it is not about absolute speed, but more about the feeling for this interactive response between the bike and the rider. It should be like a good conversation from man to machine and vice versa. This gives excitement and satisfaction. So both R1 and R6 are targeted towards rider control on every type of twisty road, and not to just ride with high speed." To achieve this target, the engineers had to make the bike as light as possible and at the same time take care of the best balance between powerful engine and controllability. Both bikes were never aimed at just high speed or high engine performance alone. In order to give both machine a pure supersports character some practical items had to be sacrificed. For example tandem riding, storage space or wind protection etc.

Now let's talk about the differences of R1 and R6.

Miwa: "R1 is all about 'How to control the brutal power'. When you ride the bike with 70-80% of it's performance potential, you feel a lot of fun. In a way it is quite suitable also for twisty public roads due to a good handling character. However, if you try to exploit the bikes full potential, you have to be more than 100% alert to control it."

This demonstration shows the different "ideal" lines of both bikes. Just click on 'Demonstration R1&R6' to run the animation.

R6: control of performance & chassis

The R6 is all about: 'Control of performance and chassis'.

A 600 cc Supersport is a perfect balance between engine performance and riding character. It is more relaxing to enjoy the full potential of the R6, since the bike's behavior is different to R1. One of the most attractive features obviously is the engine character: There is no sudden slip of the rear wheel, because the high rpm level gives a smooth power delivery. This has advantages, when cornering and realizing that you need to change your line. You can stabilize the R6 even during banking with the throttle open and you do not risk a sudden tail slide. R1: control the raw power

If you turn the throttle too sudden on an R1 you create an instant enormous power delivery to the rear wheel. That is different from the R6. And indeed, not may parts are in common between R6 and R1. Let's take the chassis: Both have a Deltabox aluminum structure, but both with different layout. The R1 uses the engine block as a stressed member, but still part of the strength of its chassis is given by the lateral box type structure. The R6 however uses the engine as major element to connect the head stock with the swing arm pivot. It is a matter of weight versus speed and performance, which requires a stiffer chassis connection for R1.

Chassis

The advantage of R6 chassis layout however: lighter weight and slim shape around the tank area.

Even with the weight difference of "only" 6 kg (175 versus 169 kg dry weight) the R1 needs comparatively more force from its rider to direct it around corners. This is a result of total chassis layout including rider position and weight distribution. Together with a caster angle of both 24°, the R6 has only 81 mm trail & 1380 mm wheel base and R1 92 mm trail & 1395 mm wheel base. These figures are expressing the technical background for the different handling character also.

Miwa:

"So it becomes obvious when taking a closer look, that the R6 and the R1 are bikes for different riding style and the enthusiast should make up his mind depending on what he prefers. The R1 needs certainly more alertness and careful operation than the R6 on twisty roads or circuits."

Hennes Fischer, Yamaha product planning consultant, openly says: "I had tracks, where I was faster and felt safer with the R6. The R1 requires lots of constant attention. If you ride on very twisty circuits, I need too much attention to control the power of the R1. The R6 simply gives me more room to concentrate on my line. Of course still the R1 is 100% adrenaline, when opening the throttle. In the end you have to decide your personal priorities."

Engine:

When taking a closer look to both engines, you realize what Mr. Miwa means with different character. It is not only the top performance of 120 HP versus 150 HP. The torque curve is entirely different, as you can see in the illustration of cornering method. The R6 needs much higher rpm, where the R1 delivers already enormous power from 2000 rpm onwards. Of course this "power from below" makes riding very relaxed in a way, that you don't need to shift a lot and in almost every situation there is enough forward thrust.

Miwa:

"R1 and R6 of course have a similar image, but in fact they have quite a different character. Both development teams worked independent and tried to make the best supersport machine in the category!"

1998 Yamaha R1/YZF-R1

___________________________________________________________________

1998

to 1999 - The First Yamaha R1/YZF-R1

“The ultimate cornering Master (Yamaha R1/YZF-R1)”

- Yamaha

1998 Yamaha R1/YZF-R1

1998 First generation: 150 HP, 177 kg

The first R1 shook the motorcycle world by putting the 1000cc class supersports back on the map. Japanese competitors had launched 900cc models in the ‘90s aiming for the best compromise in power and in weight. Yamaha decided for a ‘no-compromise’ approach. The development team were given 3 clear targets: to make the highest power, the lowest weight and the most compact dimensions.

What Yamaha’s engineers created was a new 998cc engine featuring a 5-valve design, big-bore 40mm downdraft carburettors and 4 into 1 exhaust featuring Yamaha’s EXUP system for improved midrange (which the first generation R1 was famous for).

The compression ratio was 11.8 to 1 with a bore and stroke of 74 x 58 mm.

The cylinder and crankcase were designed in 1 piece which was lighter and

stronger than the conventional ‘bolted’ designs. The complete engine

was designed to be a stressed member in the latest generation aluminium Deltabox

frame.The first R1 shook the motorcycle world by putting the 1000cc class supersports back on the map. Japanese competitors had launched 900cc models in the ‘90s aiming for the best compromise in power and in weight. Yamaha decided for a ‘no-compromise’ approach. The development team were given 3 clear targets: to make the highest power, the lowest weight and the most compact dimensions.

What Yamaha’s engineers created was a new 998cc engine featuring a 5-valve design, big-bore 40mm downdraft carburettors and 4 into 1 exhaust featuring Yamaha’s EXUP system for improved midrange (which the first generation R1 was famous for).

The engine featured a revolutionary new tri-axis design where the crankshaft, drive shaft and main shaft are not arranged in a horizontal line (as normal) but in a triangular layout so that the overall engine build could be much shorter.

This more compact engine design enabled a layout with a very short wheelbase (1395mm) for excellent handling, combined with a very long swingarm which is beneficial for traction and stability. This layout structure is still up to date today, and many competitors have followed this development.

1998 Yamaha R1/YZF-R1

In 1999 the R1 received new colouring and graphics to remain current and up-to-date.

1998 Yamaha R1/YZF-R1 Specifications

Engine

Engine type Liquid-cooled, forward inclined parallel 4-cylinder, DOHC, 5-valve per cylinder

Displacement 998 cc

Bore x stroke 74.0 x 58.0 mm

Compression ratio 11.8 : 1

Maximum power 110.3 kW (150 HP) @ 10,000 rpm

Maximum torque 108.3 Nm (11.0 kg-m) @ 8,500 rpm

Lubrication system Wet sump

Fuel System BDSR40 with TPS system

Clutch type Wet, multiple disc

Starter system Electric

Transmission system 6 speed

Primary reduction ratio 1.581

Secundary reduction ratio 2.688

Final transmission Chain

Ratios gearbox 1st 2.500

Ratios gearbox 2nd 1.842

Ratios gearbox 3rd 1.500

Ratios gearbox 4th 1.333

Ratios gearbox 5th 1.200

Ratios gearbox 6th 1.115

Chassis

Chassis Aluminium Deltabox II

Front suspension system Telescopic fork, upside- down, Ø 41

Front wheel travel 135 mm

Rear suspension system Truss-type aluminium swinging arm Monocross system

Rear wheel travel 130 mm

Caster angle 24°

Trail 92 mm

Front brake Double-disc, Ø 298 mm

Rear brake Single disc, Ø 245 mm

Front tyre 120/70 ZR17

Rear tyre 190/50 ZR17

Front rim 17" x MT3,50

Rear rim 17" x MT6,00

Dimensions

Overall length 2,035 mm

Overall width 695 mm

Overall height 1,095 mm

Seat height 815 mm

Wheelbase 1,395 mm

Minimum ground clearance 140 mm

Dry weight 175 kg

Fuel tank capacity (reserve) 18 L

Specifications and appearance of Yamaha products shown here are subject to change without notice and may vary according to requirements and conditions. For further details please consult your Yamaha dealer.

___________________________________________________________________________________

2000

to 2001 - The world is a curve - Second Generation R1/YZF-R1

“The ultimate cornering Master (Yamaha R1/YZF-R1)”

- Yamaha

2000 Yamaha R1/YZF-R1

The model update in 2000 was aimed at improving the handling

and creating a more linear throttle response. Using the same basic components

and layout the engineers fine-tuned many details to maximise the potential

of the motorcycle. The most noticeable detail changes were the modified carburettor

settings, reduced frictional losses in the engine, improved gearbox and many

weight-saving changes throughout the model.

The silencer was changed to titanium and the bike’s bodywork was totally

new.Emissions were reduced in accordance to EU-1 regulations by an air intake system (AIS). Total weight was reduced to 175 kg.

2001 Yamaha R1/YZF-R1

The year 2001 saw a new colouring and graphics scheme used to keep the YZF-R1

popular and up-to-date.R1 The world is a curve: Cornering that's what supersport is all about!

Second generation R1: the engineers focused on cornering and handling.

Nicknamed THE ONE, the second generation R1 focuses on what supersport excitement is all about: cornering, enjoyment of winding roads and racetrack.

In the past the increase of horsepower and top speed triggered the interest of many supersport riders, high performance machines of top capacity categories have reached a level, which requires a constant attention from the rider, when riding at higher speed.

Yoshikazu Koike took over the project leadership from Kunihiko Miwa nicknamed "Mr. No Compromise", who is the legendary creator of the original R1. He describes the key-points of the new development: "Our biggest challenge was how to keep the great qualities of the R1 while continuing its evolution to a new level. Our aim was creating a machine that responds directly to the rider's actions and a very high level of cornering performance."

Riders confirmed the direction. Hennes Fischer, product planning consultant: "I felt at home on THE ONE already after the first corner. I attacked the corners in Fukuroi (Fukuroi is a Yamaha test track in Japan) as if I knew the bike already for a while. The whole package, riding position, suspension setup and performance control work so nicely together, that you never feel fighting against the bike, but the bike assists you in your actions. In other words: THE ONE brakes as you order it through the lever, it flips into corners with your body movements and it accelerates precisely every millimeter of throttle opening. The bike is like a top level aerobatics - its precision flying."

THE ONE is demanding on the other hand: To enjoy the potential of it you need experience and you have to ride it also with physical input and strength to be rewarded with the direct feed back of the machine. Body movement during cornering for example supports riding precision rather than disturbing it.

Hajime Nakaaki, responsible for chassis design of THE ONE explains how the engineers achieved the 'YAMAHA handling': "The key is the perfection in design of the steering assembly and the head pipe. Basically, achieving rigidity means: fixing the head pipe solid in place, and then making the pivot assembly resistant to distortion. But a motorcycle does not just drive straight but constantly has directional changes from left to right. We concentrated our efforts in perfecting this most basic character of a motorcycle as such."

The changes included a complete new front fork with 15 mm lesser wheel travel ( 120 mm), a thicker inner tube and a thinner walled stock for the outer tube. Also a completely new designed 3rd generation of Deltabox frame with detachable rear subframe and the asymmetric rear arm as well as a modified rear suspension. The engine was raised by 20 mm to concentrate the mass around the rolling axis. Even the rider position is nearer to the rolling axis to achieve YAMAHA handling.

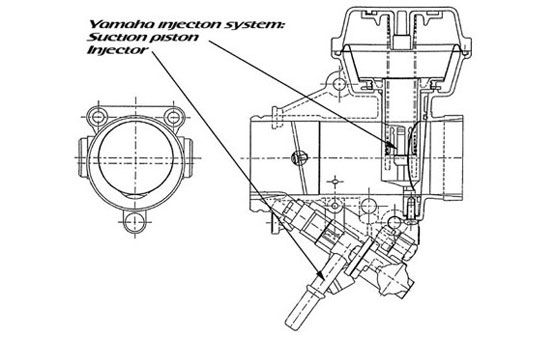

Project leader Koike adds: "The place where we did discuss and exchange opinions between us was the small meeting room behind the pit lane on our test track. This is one of the most important hidden specs you won't see in any catalogue. I believe it is those high-powered meetings that led to the creation of this amazing machine that clears high EU2 emission standards and at the same time proposes the standard for next generation supersport." Experienced riders know: 'power is nothing without control'. Just horsepower may be nice to show your friends in a glossy leaflet, but when it comes down to use such high power bikes like the R1 you need proper control. That is why the new R1 engine has its hidden strength supported by the new fuel injection system and a completely new EXUP exhaust management system. Kenji Abe, responsible for engine design explains: "For the first time on a production motorcycle we used a Vacuum-controlled Electronic Fuel Injection. This system allows an ideal air/fuel mixture in low rpm-range by controlling the air intake. It does not require complicated electronic controls and it combines the advantages of a carburetor with those of a today's fuel injection. In other terms you can say it is a fusion of analog and digital."

This system "fuel injection with suction piston" uses a free suction driven valve piston to regulate air intake flow independently from electronic control. This ensures an optimum air volume without "smart electronic interference". On the other hand a microcomputer control collects data from various sensors to ensure an optimum fuel supply with the right air/fuel mixture. This is the secret giving THE ONE such direct throttle response.

(Interesting note: Yamaha used two suppliers with greatest experience in this field: Mikuni for the throttle sensor and Mitsubishi for the electronic control unit.)

The new lighter and more compact EXUP system in the exhaust system supports the fuel injection to maintain the best possible flow management of intake and exhaust gases. Two valves instead of one on the previous R1 are responsible for cylinder 1 & 4 respective 2 & 3. That's why the R1 engine has such a high torque and control feeling over all its rpm range.

Product planner Shinichiro Nishimura is convinced: " There are a lot of competitors out there in our industry, and if you were going to choose one model that shows what sets Yamaha apart from the rest, I think that this may be it! THE ONE will touch the heartstrings of the experienced supersport user and I think they know what really matters at this level of performance is Man Machine Communication."

That's what THE ONE is all about.

2000 Yamaha R1/YZF-R1 Specifications

Engine

Engine type Liquid-cooled, forward inclined parallel 4-cylinder, DOHC, 5-valve per cylinder

Displacement 998 cc

Bore x stroke 74.0 x 58.0 mm

Compression ratio 11.8 : 1

Maximum power 110.3 kW (150 HP) @ 10,000 rpm

Maximum torque 108.3 Nm (11.0 kg-m) @ 8,500 rpm

Lubrication system Wet sump

Fuel System BDSR40 with TPS system

Clutch type Wet, multiple disc

Starter system Electric

Transmission system 6 speed

Primary reduction ratio 1.581

Secundary reduction ratio 2.688

Final transmission Chain

Ratios gearbox 1st 2.500

Ratios gearbox 2nd 1.842

Ratios gearbox 3rd 1.500

Ratios gearbox 4th 1.333

Ratios gearbox 5th 1.200

Ratios gearbox 6th 1.115

Chassis

Chassis Aluminium Deltabox II

Front suspension system Telescopic fork, upside- down, Ø 41

Front wheel travel 135 mm

Rear suspension system Truss-type aluminium swinging arm Monocross system

Rear wheel travel 130 mm

Caster angle 24°

Trail 92 mm

Front brake Double-disc, Ø 298 mm

Rear brake Single disc, Ø 245 mm

Front tyre 120/70 ZR17

Rear tyre 190/50 ZR17

Front rim 17" x MT3,50

Rear rim 17" x MT6,00

Dimensions

Overall length 2,035 mm

Overall width 695 mm

Overall height 1,095 mm

Seat height 815 mm

Wheelbase 1,395 mm

Minimum ground clearance 140 mm

Dry weight 175 kg

Fuel tank capacity (reserve) 18 L

Specifications and appearance of Yamaha products shown here are subject to change without notice and may vary according to requirements and conditions. For further details please consult your Yamaha dealer.

___________________________________________________________________________________

2002

to 2003 - Redefined - Third generation R1/YZF-R1

“The ultimate cornering Master (Yamaha R1/YZF-R1)”

- Yamaha

2002 Yamaha R1/YZF-R1

A new generation of R1 was developed for (even) better cornering

performance and more control for the rider.

A completely new frame (with detachable sub-frame) was developed and optimized to work with the new front forks and new rear suspension. The front end geometry was fine-tuned and the fork inner tubes were increased in diameter from 41 to 43 mm. The front fork stroke was reduced from 135 to 120 mm providing better control and feeling when braking and cornering.

The new engine was mounted higher in the frame which is much closer to the

rolling axis of the bike. A fuel injection system was added and met the tougher

EU2 emission standards with ease.A completely new frame (with detachable sub-frame) was developed and optimized to work with the new front forks and new rear suspension. The front end geometry was fine-tuned and the fork inner tubes were increased in diameter from 41 to 43 mm. The front fork stroke was reduced from 135 to 120 mm providing better control and feeling when braking and cornering.

The fundamental dimensions and architecture of the engine was inherited from the original R1 but the vast majority of the components were new. The air intake was controlled by a ‘suction piston’ type of valve to ensure a smooth and direct throttle response. Bore x stroke was now 74 x 58 mm and the airbox intake was altered to face forward accessing cooler air. As a result of these changes the HP was increased to 152 and dry weight was reduced to 174 kg.

The bodywork was again completely new. The exhaust system was changed to a 4 into 2 into 1 layout and now completely made of titanium, including the header pipes.

The new, asymmetrical swingarm allowed an unobstructed route for this exhaust system. The wheels were lighter and the new brake system was easily recognizable by the orange callipers that replaced the blue ones on previous models.

One additional detail improvement was made with the addition of a shift indicator lamp.

2003 Yamaha R1/YZF-R1

2003 saw another colouring and graphic change to keep the YZF-R1 popular

with the most up-to-date riders.2002 - 2003 Yamaha YZF-R1 : A closer look at engineering details

The development priorities of the new R1 are handling and controllability. What are the engineering ingredients that make the bike faster in corners and at the same time even easier to handle?

"It is very reassuring to see the result of the web questionnaire", Yoshikazu Koike looks with a smile to the facts and figures on paper "almost 75% of the many thousands of respondents mentioned, that cornering performance is more important to them than just simple horsepower or top speed".

This confirms the desire of most supersport riders to enjoy sport bikes in an environment they are made for: winding roads and tracks.

Lets have a closer look at the solutions behind the R1, to achieve the targets that have been laid down in the concept catalogue.

The following is a summary of the most important features of 2002 model R1 (of course there are lots of other changes too…).

The main areas:

Chassis

- Mass concentration around the rolling axis

- High chassis rigidity

- Refined steering assembly and front suspension setting

Engine

- Sensual Throttle Response

- Enhanced over-rev characteristics

- Other detail solutions

Chassis - Part 1

Target of development - Mass concentration around the rolling axis.

R1 components placed as near as possible around the rolling axis to improve

- Linear banking character

- Quick handling

This is achieved by:

1. Engine position 20 mm higher and therefore near to the rolling axis

2. Asymmetrical swingarm to allow the muffler to be placed with a narrower routing close to the body

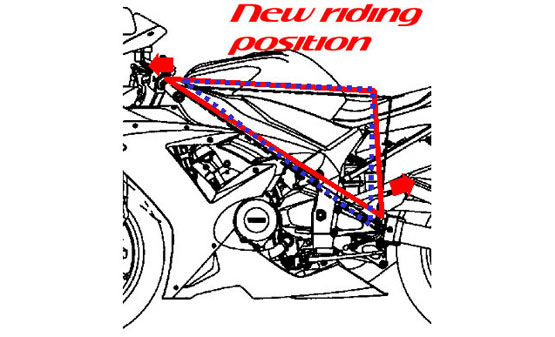

3. Revised Riding Position

The 20 mm higher engine position brings the main masses nearer to the rolling axis. The rolling axis of the bike is a hypothetical line, which changes position during riding, depending on the forces applied to the machine. This axis is the key for the handling character of a motorcycle. The less mass one has to move at a distance around this axis, the easier the bike feels when going into and out of corners.

The muffler needs to be placed as close as possible to the bikes body. This allows sufficient ground clearance during cornering and also concentrates the mass of the whole exhaust system near to the rolling axis. To achieve this the swingarm of R1 is asymmetrical, in order to allow the muffler to be placed "inside".

The rider's weight has a great influence on handling character. Just like the other components of a bike, ideally the rider should be placed as near as possible to the rolling axis. However comfort and ergonomics of man needs to be considered too and is usually contradictory to pure engineering requirements. The Riding position of R1 has been changed considering both factors. As you can see in the illustration (red line is new R1, blue line is 2001 model), footrest position is moved backwards and handlebar position is further forward. To balance the riders weight distribution in a better way.

Chassis - Part 2

Target of development - High chassis rigidity

R1 rigid chassis will result in

- Sharp response to riders input (steering braking etc.)

- Precise feedback from riders action and road surface and condition

This is achieved by:

1. Deltabox III chassis with 30% increased rigidity

2. Rigid new swingarm

3. 43 mm front fork (2 mm size up at same weight)

4. One piece forged handlebars (to transmit the precise feedback to the rider)

The Deltabox III represents the 3rd generation. This chassis is lighter and has a 30% increased rigidity and new geometry. Also the rear sub-frame is detachable.

The swingarm has a new asymmetrical layout. To avoid interference with exhaust pipes, the right-hand side is curved. Also the rigidity of the unit itself is in line with the new Deltabox III chassis.

The front fork diameter increased from 41mm to 43 mm. The increased rigidity of the fork was a necessary result of the new chassis layout and contributes to direct feel for the road and general stability.

It seems a small thing at first, but the new forged handlebars contribute to the direct feedback between rider and road. The enhanced rigidity of these aluminum bars allow very little flex during operation and improve the feeling for what is happening through the front steering assembly

Chassis - Part 3

Target of development- Refined steering assembly and front suspension setting

A new front fork and suspension setting results in

- Active banking character into corners

- Possibility to accelerate earlier and with better grip out of corners

This is achieved by:

1. New steering assembly settings

a. Reduced Fork Offset 25mm (-10mm)

b. Increased trail 103mm (+11mm)

2. Reduced Front Fork Stroke of 120mm (-15mm) for reduced pitching

3. New Swing-arm pivot axis position:

a. Raised by 17.5 mm

b. Increased angle (11.8°)

4. Higher spring rates, increased damping setting range and adjustment possibilities.

The offset reduction by 10 mm had a positive effect on handling, and the increased trail of 11 mm (now 103 mm total) increased feedback and cornering stability at the same time.

The stroke was reduced from 135 mm to 120 mm. This reduces pitch and movement of the machine during acceleration and braking and contributes significantly to stability in cornering and at the same time increases feedback from road surface.

The swingarm pivot position has been raised by 17,5 mm. As a result the swingarm angle was increased. This contributes to better traction during acceleration, in particular out of corners, due to a better absorption of the chain forces influencing the rear wheel.

The spring rates of front and rear suspension were increased, to adapt to the higher rigidity of the chassis. Also the adjustment range has been increased and the rider can select between 20 steps of adjustment both on front and rear suspension.

Engine - Part 1

Target of development- Sensual Throttle Response

In order to enable the rider to perform

- Early throttle opening out of corners

- Precise performance control

This is achieved by:

1. Fuel Injection with Suction Piston Intake System (Yamaha patented system)

2. Dual EXUP system with compact layout and 2-shaft design (-500 g)

Fuel injection guarantees a precise "digital" mixture of fuel and air and is a good feature to ensure low emissions and best mixture setting throughout the whole rpm range. Carburetors on the other hand have a better "analogue" response feeling and a smoother throttle pick up. The R1 new FI- system combines both system advantages. A suction valve acts like a carburetor and regulates the throttle pick up and a direct injection contributes with the correct mixture, microchip controlled and feed with information from several sensors. The result is a better throttle control which enables the rider to activate the right amount of power at any engine revolution almost linear to throttle grip operation.

The EXUP system is a valve to consol the gas flow in the exhaust system, to strengthen the engine character (in particular in midrange). The new system has 2 valves instead of one and is smaller and lighter. It operates electronically controlled, taking gear position and engine revolution into consideration. A new high torque electric motor improves responsiveness and drivability.

Engine - Part 2

Target of Development- Enhanced over-rev characteristics

To make efficient use of wider power band

This is achieved by:

1. Electronic fuel injection management

2. New air-cleaner box with forward facing air intake

3. New exhaust layout 4in2in1 system

Yamaha new fuel injection system, enables the rider to "over-rev" the engine , while still keeping a proper fuel & air mixture. There is no engine "cough" on high revolutions, when the rider decides for no shift up between corners.

To supply cooler air to air-box, the air intake has been moved forward. Fresh air enters the air-box from the front of the motorcycle directly. Cooler air has a higher density and this is beneficial to performance output.

The new exhaust layout routes the 4 pipes into a 2 pipe chamber and then into the single pipe connecting the muffler. This construction increases engine character and boosts performance in midrange.

Engine - Part 3

Other detail solutions to support development targets:

1. New brake system to increase performance and controllability

2. High silicon-content alloy cylinder sleeve and new design piston rings

3. Uprated carburised connecting rods

4. Lighter exhaust valves

5. Iridium spark plugs

6. Better cooling: New radiator and oil cooler

The brake system features new calipers to increase brake performance and controllability. The pistons of the front calipers are changed to alloy and new sintered pads are used. Also the hand-lever ratio has been changed. To balance the brake forces between front and rear, the rear brake caliper has been changed to a 2piston type and the disc diameter could be reduced by 25 mm to now 220 mm (for light weight).

The new aluminum sleeves have a higher silicon content, in order to decrease oil consumption and at the same time to ensure lowest friction between piston and sleeve. The new piston rings have different material in order to fit to the new sleeves.

The new up rated carburised connecting rods have highest rigidity at a low weight.

Lighter exhaust valves ensure a higher engine revolution combined with high reliability.

The new Iridium spark plugs ensure a more stable combustion. Iridium melting point is very high (2150 degree centigrade) , and therefore has a higher heat resistance than normal spark plug. The durability is 1.5 times longer than a normal spark plug at the same condition.

Keeping the engine cool results in better performance even in "hot" conditions. The new radiator in combination with a higher performance fan has increased cooling capacity by a 20 % better airflow, comparing to previous model. Also 20% increase in cooling capacity was achieved by a new oilcooler layout.

YZF-R1 Third vs Fourth generation: The real stuff

There has never been a bike running off Yamaha's production line, that had more influence from GP and World Superbike than the third generation R1.

An extreme machine like the R1 usually provokes the same doubtful question: Lighter, faster, more radical- when does this development come to an end? The answer is as simple as it is obvious: there will never be an end to technical development. Approaching the question from a philosophical point of view, we need to ask the question: why should there be an end to these developments? The new R1 is simply better than ever before. And better does not mean only more powerful and faster. There is a more sophisticated, holistic development philosophy behind the R-series.

Leading motorcycle development

Let's have a brief look back in history: Development in the seventies and early eighties focused a lot on increase of horsepower. When the first 100 HP machines appeared, the same doubtful question was raised. But brakes and chassis technology improved a lot in the following years and a 100 HP machine was easier to handle than a 50 HP machine a couple of years earlier. Supersport machines like the FZR 1000 in 1988 and ultimately the first R1 in 1998 became more powerful, but at the same time they became more controllable and lighter due to use of aluminium chassis components, better brakes, better suspension and new design and layout. No doubt, supersport is leading motorcycle developments and there is a lot of spin off to other bike categories, which benefit from supersport technology.

However the goalposts have changed in the recent years. The first R1 focused on lightweight, the second generation in 2002 focused on controllability and handling. The third generation R1 has a more holistic development philosophy, the focus is on the rider's viewpoint of what the most ideal supersport machine should be: most powerful, excellent handling and still controllable.

Humachine Technology

The R1 development team consists of a bunch of enthusiasts themselves, who acquired unique skills in the various areas of motorcycle design: from engine, chassis and suspension, to ergonomics, aerodynamics and material science. The result of their work is an entirely new bike with not only unmatched specification, but also it is the pinnacle of what Yamaha calls "Humachine Technology". The phrase is an abbreviation of human & machine and stands for a holistic approach which will make the rider feel excited and, at the same time, confident on such a high performance machine regardless of his skill and speed.

Yamaha's test riders have a deep knowledge base of how a bike should handle. One of them is an ex-professional racer: "It was hard work to get every single component of the bike to work as we wanted it. But the new R1 is now just breathtaking. With 170 to 180 HP (depending on ram air pressure) at my fingertips, I could never feel the bike would be out of control. It just handles in a way we could not imagine a few years ago."

This is not only the low weight with a power to weight ratio of 1:1, but it is the integration of parts into each other. For example the engine construction was significantly influenced by chassis & handling requirements. That's the reason why the new power-plant has a 40° cylinder angle to give the frame more room for a straight line from headstock to pivot point at the rear swing arm axle, resulting in a 200 % stiffer frame!

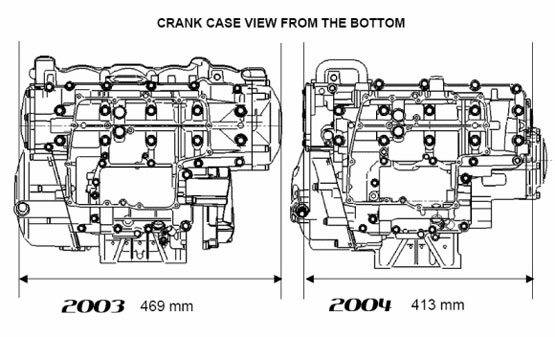

The base layout of the engine is based on the GP1 racer, and the bore was increased by 3 mm with a shorter stroke to enable higher rpm. Usually this would result in a 12 mm increase in width of the engine but the engine block is only 2,8 mm wider. To achieve this the cylinder pitch was reduced to levels never reached before. However, by moving the generator behind the cylinder block the total engine size could be even further reduced, so that the engine as a package is smaller than ever before!

Communication between man and machine

The test rider is convinced: "For me the key word for R1 is high control feeling. Front end feel is the key to fast corner entry, for rapid corner exit you need stability and good traction. The problem we were confronted with this high performance engine was to find a good suspension balance during hard acceleration because this powerful engine upsets the rear suspension especially in the lower gears. We solved it and I think the new R1 is as close to a race bike as you can get while still having a fantastic road bike at the same time."

Because of this high control feel the rider is confident and he will enjoy the R1's incredibly quick turn-in characteristics and rapid corner exits.

He explains further: "The gearbox also plays an important role in the R1 cornering ability. It is a real race close ratio gearbox, where you always find a best gear for a certain corner and you will always be in the right rpm range. A four stroke engine has to run in the right rpm range during cornering because of its rotating mass. If the engine is revving too low during cornering the bike will under steer. That is why the gearbox is so important for this bike."

A lot of this knowledge materialised in the new R1 came from Yamaha MotoGP machines. This bike does exactly what the rider wants. Both experts and average riders can experience this behaviour and thrill. And that is what makes the new R1 so exciting!

Not a replica, but the real stuff

Unlike racer replicas which copy the outside of racer machines, the new R1 is based on the inner virtues of a racing machine. There is no artificial styling or gimmick, every part has a function and contributes to the bikes total performance.

The R1 is a perfect example of a mechanical beauty that results when form truly expresses its function. That is the true aesthetic attraction of the new R1. In simple terms: "What you see is what you get."

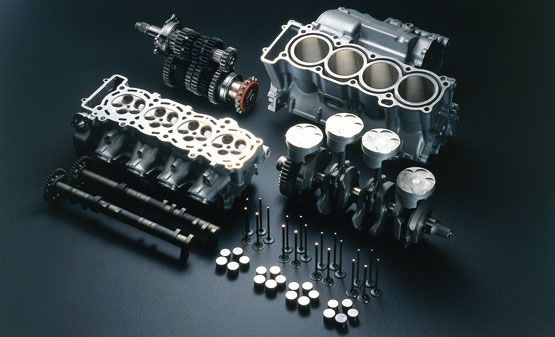

YZF R1: ALL-NEW ENGINE

A whole new world of performance

The engineers have developed an all-new in-line four cylinder powerplant whose genetic make up is heavily influenced by the very latest MotoGP-developed technology.

The new engine on the third generation R1 is the most advanced design ever used on a production Yamaha, and by using the very latest race-bred systems and designs, maximum power output is boosted by over 13 per cent to 172 HP at 12,500 rpm, a figure which rises to 180 HP with the forced air intake operational!

Optimized 40 degree cylinder angle

Yamaha's R-series models have always been developed using a holistic approach in which every single component is developed not only to perform its own specific role efficiently, but also to complement the performance of all other components wherever possible.

An excellent example of this totally integrated design philosophy can be seen in the adoption of the new cylinder layout, which is angled forwards at 40 degrees.

This configuration is similar to the layout used on Yamaha's MotoGP racing machinery, and it allows greater freedom in the development of a much stiffer chassis. By sloping the engine forwards at 40 degrees, the new generation R1 frame has a virtually straight, unimpeded run from the headstock through to the swingarm pivot point, which, in chassis terms, is an idealised layout.

There are two major benefits from using this 40 degree engine position. Firstly, because the main spars are now able to take the most direct path to the swingarm pivot, the new R1's frame rigidity is increased significantly. Secondly, because the cylinder head now sits below the route of the twin spars, the overall width between the spars is greatly reduced.

This in turn allows the fitment of a slimmer fuel tank, which makes for a more comfortable and aerodynamic riding position.

Bigger bore closed-deck cylinder

In the quest for greater power Yamaha's engineers have increased bore size to 77 mm, while stroke is reduced to 53.6 mm, and this free-revving shorter stroke engine now delivers peak power at 12,500 rpm, some 2,000 rpm higher than previously.

The new closed-deck cylinder design offers high levels of rigidity, and this has made it possible to reduce the thickness of alloy between each individual cylinder bore to only 5mm.

Because the new frame is much stronger, the new 40° slant block motor is no longer employed as a fully-stressed member, and the new cylinder is now separate from the upper crankcase, and not a unified design as seen on the '03 model.

Compact high-compression cylinder head

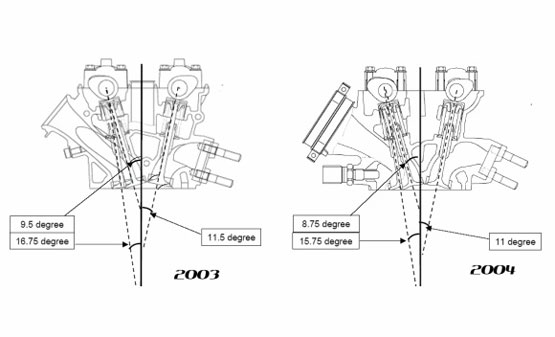

One of the significant performance enhancing components on the new R1 is its newly designed cylinder head. The DOHC 5-valve layout now features narrower valve angles, with the centre intake valve set at 8.75 degrees, while the outer intake valves are angled at 15.75 degrees, and the two exhaust valves positioned at 11 degrees.

The shape of the ports and combustion chamber design has also been modified, and the squish area has been changed to give a higher compression ratio of 12.4:1

Lightweight low-inertia internals

New 77mm diameter short-skirt forged pistons and new carburised connecting rods drive a lightweight crankshaft assembly, and although this new set-up is designed to handle higher engine speeds and increased levels of power, it is actually lighter than the 2003 machine's design. The reduced inertia of the '04 engine internals complements the free-revving character of the new shorter stroke engine, to give the new R1 excellent throttle response over a very wide range of engine speeds.

Compact fuel injection system with motor-driven secondary throttle valves

The third generation R1 uses a new fuel injection system featuring twin valve throttle bodies, and this highly advanced new fuel supply system features digitally-controlled motor-driven secondary butterfly valves that actively control the air flow. The result is class-leading driveability and linearity together with precision throttle response that makes for previously unattainable levels of controllability.

Yet, at the same time as being a high-tech digitally-controlled design, the quality and characteristics of this new fuel injection system have ultimately been set by the test riders that spent many hours fine tuning the mapping.

As well as being one of the most advanced fuel supply systems in the supersport class, this is also one of the most compact, as it has to fit in between the spars on the new slimline frame. By reducing the pitch between the throttle bodies the overall dimensions have been minimised, and this sophisticated new digitally-controlled system is as compact as that fitted to a 600.

Forced air intake

As well as increasing performance at higher speeds, this new forced air intake system offers a number of other important advantages. The much smaller airbox required by this forced air system takes up less space above the engine, and this allows the fitment of a slimmer fuel tank.

Once again, this demonstrates how Yamaha's holistic approach to supersport machine design offers a wide range of advantages to the third generation R1 rider.

Lightweight close-ratio tri-axis transmission and compact clutch

Like its predecessor, the third generation R1 features Yamaha's innovative space-saving tri-axis 'stacked' transmission whose staggered shaft configuration makes for extremely compact front-to-rear engine dimensions.

To optimise the performance from the more powerful and higher revving engine which now pushes out 172 HP at 12,500rpm, a new close ratio 6-speed transmission has been developed.

Lightweight titanium underseat exhaust system

One of the most significant stylistic changes seen on the new R1 is the compact new 4-into-1-into-2 underseat exhaust system. This beautifully designed system is manufactured from titanium, and as well as being lighter than the conventional layout, it also offers greater aerodynamic efficiency.

Tucked beneath the seat, the dual titanium mufflers give the R1 a slim and aggressive looking rear end, and the system has been tuned to emit a deep, strong growl that gives more than a hint that this is the most powerful Yamaha supersport ever.

The torque-boosting EXUP (Exhaust Ultimate Powervalve) system is situated where the four header pipes flow into one, and features a titanium butterfly valve for the first time.

New curved radiator design

For high levels of cooling efficiency, and also to accommodate the new 40 degree slant of the new engine, a new curved radiator is fitted. This lightweight design is wider and not as tall as the existing system, and features dual ring fans for efficient operation in all conditions.

Water-cooled oil cooler

Yet another example of Yamaha's attention to detail and desire to minimise weight is the use of a water-cooled oil cooler which is situated at the front of the lower crankcase.

Lightweight AC Magneto

A compact new gear-driven AC magneto which is situated behind the cylinder is as well helping reduce engine width which to allow for greater lean angles and to decentralise mass.

Engine Technical Highlights

- Totally redesigned in-line four cylinder DOHC 5-valve engine

- Maximum power 172 HP @ 12,500 rpm

- 180 HP @ 12,500 rpm with forced air intake

- 40 degree cylinder angle

- Redesigned cylinder head with narrow valve angle

- Increased compression ratio

- Redesigned combustion chamber

- High-lift camshafts

- Electronic fuel injection with motor-driven secondary throttle valves

- Forged pistons, carbonised conrods and lightweight crankshaft

- Reduced internal inertia

- Direct ignition

- Lightweight close-ratio 6-speed transmission

- Compact clutch

- Forced air intake system

- Separate closed deck cylinder

- Reduced pitch between cylinder bores

- Wider curved radiator with dual ring fans

- Titanium 4-into1-into-2 exhaust system with twin up-mufflers

- Lightweight EXUP system with titanium butterfly valves

- Water-cooled oil cooler

- Compact gear-driven ACM located behind cylinders

2002 Yamaha R1/YZF-R1 Specifications

Engine

Engine type Liquid cooled, 4-stroke, forward inclined parallel 4 cylinder, DOHC 20 valves

Displacement 998 cc

Bore x stroke 74.0 x 58.0 mm

Compression ratio 11.8 : 1

Maximum power 111.8 kW (152 HP) @ 10,500 rpm

Maximum torque 104.9 Nm (10.7 kg-m) @ 8,500 rpm

Lubrication system Wet sump

Fuel System Mikuni FI

Clutch type Wet, multiple disc

Ignition system TCI (digital)

Starter system Electric

Transmission system Constant mesh, 6 speed

Primary reduction ratio 1.581

Secundary reduction ratio 2.688

Final transmission Chain

Ratios gearbox 1st 2.5

Ratios gearbox 2nd 1.842

Ratios gearbox 3rd 1.5

Ratios gearbox 4th 1.333

Ratios gearbox 5th 1.2

Ratios gearbox 6th 1.115

Chassis

Front suspension system Telescopic fork

Front suspension adjustability Swingarm (Link suspension)

Front wheel travel 120 mm

Rear wheel travel 130 mm

Caster angle 24°

Trail 103 mm

Front brake Dual discs, Ø 298 mm

Rear brake Single disc, Ø 220 mm

Front tyre 120/70 ZR17M/C (58W)

Rear tyre 190/50 ZR17M/C (73W)

Dimensions

Overall length 2,035 mm

Overall width 705 mm

Overall height 1,105 mm

Seat height 820 mm

Wheelbase 1,395 mm

Minimum ground clearance 140 mm

Dry weight 174 kg

Fuel tank capacity (reserve) 17 L

Engine oil tank capacity 3.8 L

Specifications and appearance of Yamaha products shown here are subject to change without notice and may vary according to requirements and conditions. For further details please consult your Yamaha dealer.

___________________________________________________________________________________

2004

to 2006 - Reborn - Fourth generation R1/YZF-R1

“The ultimate cornering Master (Yamaha R1/YZF-R1)”

- Yamaha

2004 Yamaha R1/YZF-R1

This generation of R1 was a completely new model and for the

first time a power to weight ratio of 1:1 was reached on a production motorcycle:

172 HP, 172 kg dry weight!

New sexy bodywork was used with 4-beam headlights making it easily recognizable

from front. Clearly recognizable from the rear were the dual mufflers under

the seat: the exhaust layout was new and as before - completely made of lightweight

titanium.The engine featured lightweight internals and a new short-stroke design (bore x stroke 70 x 53.6 mm) to enable higher rpm and higher power output. Peak power was now reached at 12.500 rpm, about 2000 rpm more then in the previous R1’s.

This model also utilized a forced air intake for the first time in R1’s history. The higher intake pressure at higher speed raised the horsepower figure to a maximum of 180 in dynamic measurement! The air intake was optimized by a series of digitally controlled, motor-driven secondary butterfly valves.

Compression ratio was now 12.4 to 1 and the cylinder’s angle was inclined 40 degrees forward so the new frame’s twin spars could run more straight and narrow to the rear. The width of the frame was herby reduced by 64mm and the fuel tank was also made slimmer, for an improved riding position.

Since the cylinder head was now below the frame’s twin spars and the frame was stronger, the engine was no longer used as a fully stressed member of the chassis anymore. With this, the cylinders were now bolt-on type and separate from the crankcase’s, not a unified design as on the previous models.

Chassis geometry and components were heavily influenced from the MotoGP programme, for example the ‘upside down truss layout’ swingarm design and the radially mounted brake callipers and radial master cylinder. The new 5-spoke wheel design was also new and lighter than ever before.

2005 Yamaha R1/YZF-R1

2003 saw another colouring and graphic change to keep the YZF-R1 popular

with the most up-to-date riders.

2006 Yamaha R1/YZF-R1

2006 - Updated specifications increased the power to 175 HP, mainly due to

shorter intake valve guides.The chassis was optimized by fine-tuning many details to find a better rigidity balance. A 20mm longer swingarm was used to contribute to traction and shifts the weight balance by 1% more to the front wheel. The front fork outer tubes were now gold coloured.

2006 Yamaha R1/YZF-R1 SP

2006 SP - This year also saw the introduction of a limited-production SP

model with a slipper clutch, Öhlins suspensions (with sophisticated damping

adjustments and ride height adjustment) and forged aluminium Marchesini Y-spoke

wheels that were 400g lighter than normal wheels.A special GunSmoke colour was used for the bodywork and chassis, only 500 units were produced for Europe.

YZF-R1 Third vs Fourth generation: The real stuff

There has never been a bike running off Yamaha's production line, that had more influence from GP and World Superbike than the third generation R1.

An extreme machine like the R1 usually provokes the same doubtful question: Lighter, faster, more radical- when does this development come to an end? The answer is as simple as it is obvious: there will never be an end to technical development. Approaching the question from a philosophical point of view, we need to ask the question: why should there be an end to these developments? The new R1 is simply better than ever before. And better does not mean only more powerful and faster. There is a more sophisticated, holistic development philosophy behind the R-series.

Leading motorcycle development

Let's have a brief look back in history: Development in the seventies and early eighties focused a lot on increase of horsepower. When the first 100 HP machines appeared, the same doubtful question was raised. But brakes and chassis technology improved a lot in the following years and a 100 HP machine was easier to handle than a 50 HP machine a couple of years earlier. Supersport machines like the FZR 1000 in 1988 and ultimately the first R1 in 1998 became more powerful, but at the same time they became more controllable and lighter due to use of aluminium chassis components, better brakes, better suspension and new design and layout. No doubt, supersport is leading motorcycle developments and there is a lot of spin off to other bike categories, which benefit from supersport technology.

However the goalposts have changed in the recent years. The first R1 focused on lightweight, the second generation in 2002 focused on controllability and handling. The third generation R1 has a more holistic development philosophy, the focus is on the rider's viewpoint of what the most ideal supersport machine should be: most powerful, excellent handling and still controllable.

Humachine Technology

The R1 development team consists of a bunch of enthusiasts themselves, who acquired unique skills in the various areas of motorcycle design: from engine, chassis and suspension, to ergonomics, aerodynamics and material science. The result of their work is an entirely new bike with not only unmatched specification, but also it is the pinnacle of what Yamaha calls "Humachine Technology". The phrase is an abbreviation of human & machine and stands for a holistic approach which will make the rider feel excited and, at the same time, confident on such a high performance machine regardless of his skill and speed.

Yamaha's test riders have a deep knowledge base of how a bike should handle. One of them is an ex-professional racer: "It was hard work to get every single component of the bike to work as we wanted it. But the new R1 is now just breathtaking. With 170 to 180 HP (depending on ram air pressure) at my fingertips, I could never feel the bike would be out of control. It just handles in a way we could not imagine a few years ago."

This is not only the low weight with a power to weight ratio of 1:1, but it is the integration of parts into each other. For example the engine construction was significantly influenced by chassis & handling requirements. That's the reason why the new power-plant has a 40° cylinder angle to give the frame more room for a straight line from headstock to pivot point at the rear swing arm axle, resulting in a 200 % stiffer frame!

The base layout of the engine is based on the GP1 racer, and the bore was increased by 3 mm with a shorter stroke to enable higher rpm. Usually this would result in a 12 mm increase in width of the engine but the engine block is only 2,8 mm wider. To achieve this the cylinder pitch was reduced to levels never reached before. However, by moving the generator behind the cylinder block the total engine size could be even further reduced, so that the engine as a package is smaller than ever before!

Communication between man and machine

The test rider is convinced: "For me the key word for R1 is high control feeling. Front end feel is the key to fast corner entry, for rapid corner exit you need stability and good traction. The problem we were confronted with this high performance engine was to find a good suspension balance during hard acceleration because this powerful engine upsets the rear suspension especially in the lower gears. We solved it and I think the new R1 is as close to a race bike as you can get while still having a fantastic road bike at the same time."

Because of this high control feel the rider is confident and he will enjoy the R1's incredibly quick turn-in characteristics and rapid corner exits.

He explains further: "The gearbox also plays an important role in the R1 cornering ability. It is a real race close ratio gearbox, where you always find a best gear for a certain corner and you will always be in the right rpm range. A four stroke engine has to run in the right rpm range during cornering because of its rotating mass. If the engine is revving too low during cornering the bike will under steer. That is why the gearbox is so important for this bike."

A lot of this knowledge materialised in the new R1 came from Yamaha MotoGP machines. This bike does exactly what the rider wants. Both experts and average riders can experience this behaviour and thrill. And that is what makes the new R1 so exciting!

Not a replica, but the real stuff

Unlike racer replicas which copy the outside of racer machines, the new R1 is based on the inner virtues of a racing machine. There is no artificial styling or gimmick, every part has a function and contributes to the bikes total performance.

The R1 is a perfect example of a mechanical beauty that results when form truly expresses its function. That is the true aesthetic attraction of the new R1. In simple terms: "What you see is what you get."

YZF R1: ALL-NEW ENGINE

A whole new world of performance

The engineers have developed an all-new in-line four cylinder powerplant whose genetic make up is heavily influenced by the very latest MotoGP-developed technology.

The new engine on the third generation R1 is the most advanced design ever used on a production Yamaha, and by using the very latest race-bred systems and designs, maximum power output is boosted by over 13 per cent to 172 HP at 12,500 rpm, a figure which rises to 180 HP with the forced air intake operational!

Optimized 40 degree cylinder angle

Yamaha's R-series models have always been developed using a holistic approach in which every single component is developed not only to perform its own specific role efficiently, but also to complement the performance of all other components wherever possible.

An excellent example of this totally integrated design philosophy can be seen in the adoption of the new cylinder layout, which is angled forwards at 40 degrees.

This configuration is similar to the layout used on Yamaha's MotoGP racing machinery, and it allows greater freedom in the development of a much stiffer chassis. By sloping the engine forwards at 40 degrees, the new generation R1 frame has a virtually straight, unimpeded run from the headstock through to the swingarm pivot point, which, in chassis terms, is an idealised layout.

There are two major benefits from using this 40 degree engine position. Firstly, because the main spars are now able to take the most direct path to the swingarm pivot, the new R1's frame rigidity is increased significantly. Secondly, because the cylinder head now sits below the route of the twin spars, the overall width between the spars is greatly reduced.

This in turn allows the fitment of a slimmer fuel tank, which makes for a more comfortable and aerodynamic riding position.

Bigger bore closed-deck cylinder

In the quest for greater power Yamaha's engineers have increased bore size to 77 mm, while stroke is reduced to 53.6 mm, and this free-revving shorter stroke engine now delivers peak power at 12,500 rpm, some 2,000 rpm higher than previously.

The new closed-deck cylinder design offers high levels of rigidity, and this has made it possible to reduce the thickness of alloy between each individual cylinder bore to only 5mm.

Because the new frame is much stronger, the new 40° slant block motor is no longer employed as a fully-stressed member, and the new cylinder is now separate from the upper crankcase, and not a unified design as seen on the '03 model.

Compact high-compression cylinder head

One of the significant performance enhancing components on the new R1 is its newly designed cylinder head. The DOHC 5-valve layout now features narrower valve angles, with the centre intake valve set at 8.75 degrees, while the outer intake valves are angled at 15.75 degrees, and the two exhaust valves positioned at 11 degrees.

The shape of the ports and combustion chamber design has also been modified, and the squish area has been changed to give a higher compression ratio of 12.4:1

Lightweight low-inertia internals

New 77mm diameter short-skirt forged pistons and new carburised connecting rods drive a lightweight crankshaft assembly, and although this new set-up is designed to handle higher engine speeds and increased levels of power, it is actually lighter than the 2003 machine's design. The reduced inertia of the '04 engine internals complements the free-revving character of the new shorter stroke engine, to give the new R1 excellent throttle response over a very wide range of engine speeds.

Compact fuel injection system with motor-driven secondary throttle valves

The third generation R1 uses a new fuel injection system featuring twin valve throttle bodies, and this highly advanced new fuel supply system features digitally-controlled motor-driven secondary butterfly valves that actively control the air flow. The result is class-leading driveability and linearity together with precision throttle response that makes for previously unattainable levels of controllability.

Yet, at the same time as being a high-tech digitally-controlled design, the quality and characteristics of this new fuel injection system have ultimately been set by the test riders that spent many hours fine tuning the mapping.

As well as being one of the most advanced fuel supply systems in the supersport class, this is also one of the most compact, as it has to fit in between the spars on the new slimline frame. By reducing the pitch between the throttle bodies the overall dimensions have been minimised, and this sophisticated new digitally-controlled system is as compact as that fitted to a 600.

Forced air intake

As well as increasing performance at higher speeds, this new forced air intake system offers a number of other important advantages. The much smaller airbox required by this forced air system takes up less space above the engine, and this allows the fitment of a slimmer fuel tank.

Once again, this demonstrates how Yamaha's holistic approach to supersport machine design offers a wide range of advantages to the third generation R1 rider.

Lightweight close-ratio tri-axis transmission and compact clutch

Like its predecessor, the third generation R1 features Yamaha's innovative space-saving tri-axis 'stacked' transmission whose staggered shaft configuration makes for extremely compact front-to-rear engine dimensions.

To optimise the performance from the more powerful and higher revving engine which now pushes out 172 HP at 12,500rpm, a new close ratio 6-speed transmission has been developed.

Lightweight titanium underseat exhaust system

One of the most significant stylistic changes seen on the new R1 is the compact new 4-into-1-into-2 underseat exhaust system. This beautifully designed system is manufactured from titanium, and as well as being lighter than the conventional layout, it also offers greater aerodynamic efficiency.

Tucked beneath the seat, the dual titanium mufflers give the R1 a slim and aggressive looking rear end, and the system has been tuned to emit a deep, strong growl that gives more than a hint that this is the most powerful Yamaha supersport ever.

The torque-boosting EXUP (Exhaust Ultimate Powervalve) system is situated where the four header pipes flow into one, and features a titanium butterfly valve for the first time.

New curved radiator design

For high levels of cooling efficiency, and also to accommodate the new 40 degree slant of the new engine, a new curved radiator is fitted. This lightweight design is wider and not as tall as the existing system, and features dual ring fans for efficient operation in all conditions.

Water-cooled oil cooler

Yet another example of Yamaha's attention to detail and desire to minimise weight is the use of a water-cooled oil cooler which is situated at the front of the lower crankcase.

Lightweight AC Magneto

A compact new gear-driven AC magneto which is situated behind the cylinder is as well helping reduce engine width which to allow for greater lean angles and to decentralise mass.

2004 Yamaha R1/YZF-R1 Specifications

Engine

Engine type Liquid cooled, 4-stroke, forward inclined, parallel 4 cylinder, DOHC 20 valves

Displacement 998 cc

Bore x stroke 77.0 x 53.6 mm

Compression ratio 12.4 : 1

Maximum power 132 kW (180 HP) @ 12,500 rpm with direct air induction / 126.4 kW (172 HP) @ 12,500 rpm without direct air induction

Maximum torque 110.1 Nm (10.9 kg-m) @ 10,500 rpm with direct air induction / 106.6 Nm (10.6 kg-m) @ 10,500 rpm without direct air induction

Lubrication system Wet sump

Fuel System Fuel injection, motor-driven secondary throttle valves

Clutch type Wet, multiple disc

Ignition system TCI (digital)

Starter system Electric

Transmission system Constant mesh, 6 speed

Primary reduction ratio 65/43 1.512

Secundary reduction ratio 45/17 2.647

Final transmission Chain

Ratios gearbox 1st 2.533

Ratios gearbox 2nd 2.063

Ratios gearbox 3rd 1.762

Ratios gearbox 4th 1.522

Ratios gearbox 5th 1.364

Ratios gearbox 6th 1.269

Chassis

Chassis Deltabox V aluminium

Front suspension system Telescopic fork, Ø 43 mm

Front wheel travel 120 mm

Rear suspension system Swingarm (Link suspension)

Rear wheel travel 130 mm

Caster angle 24°

Trail 97 mm

Front brake Dual floating discs, Ø 320 mm

Rear brake Single disc, Ø 220 mm

Front tyre 120/70 ZR17M/C

Rear tyre 190/50 ZR17M/C

Front rim 3.5

Rear rim 6

Dimensions

Overall length 2,065 mm

Overall width 720 mm

Overall height 1,105 mm

Seat height 835 mm

Wheelbase 1,395 mm

Minimum ground clearance 135 mm

Dry weight 172 kg

Fuel tank capacity (reserve) 18 L

Engine oil tank capacity 3.8 L

Specifications and appearance of Yamaha products shown here are subject to change without notice and may vary according to requirements and conditions. For further details please consult your Yamaha dealer.

___________________________________________________________________________________

2007

to 2008 - State Of The Art Race Technology - Fifth generation R1/YZF-R1

“The ultimate cornering Master (Yamaha R1/YZF-R1)”

- Yamaha

2007 Yamaha R1/YZF-R1

The fifth generation of the YZF-R1 targeted the handling of

600cc motorbikes. To achieve this, a lot of work was done on the rigidity

balance of the whole chassis.

A new frame, new swingarm and new front fork were the result of this target along with new 6-pot brake callipers setting new standards regarding braking performance.

The air intake featured YCC-T (a kind of ‘fly-by-wire’ throttle

technology from MotoGP) and YCC-I (a variable intake that switches from long

to short intake funnels at higher rpm). The compression ratio was increased

to 12.7 to 1 and a 4-valve engine design (all previous generations had 5 valves)

incorporates lightweight titanium valves. Horsepower output was upped to 180

HP with a dry weight of just 177 kg.A new frame, new swingarm and new front fork were the result of this target along with new 6-pot brake callipers setting new standards regarding braking performance.

A 3-way catalyser enabled The R1 to comply with tougher EU-3 regulations and a slipper clutch, similar to the one used on the SP model the year before, was now fitted as standard equipment.

2008 Yamaha R1/YZF-R1

2008 - Again new colouring and graphics were introduced in 2008.The fifth generation R1: Precision Engineering

"We target expert skilled riders with the R1", says Product Planning division manager Takeshi Higuchi. "People who go on racetracks, and who have very high requirements towards riding dynamics."

In addition to that, the bike should also provide a competitive base for World Superbike Racing. "The chassis was to become much more agile while keeping the stability. Our handling target was to come close to the R6. That is a big benefit for racing, but it's also good for normal road use. You can ride on secondary roads with an extremely enjoyable handling!"

Chassis:

What are the elements that make the more sporty setup of the chassis? The aluminium frame is completely new, with an ideal 'stiffness balance'. Step by step the engineers and test riders developed a construction which is very rigid in certain areas – for example the mounting points – and at the same time offers a certain flexibility and 'feel' in other areas. For example, the wall thickness in the main frame side panels was reduced while the cast areas at the mountings were strengthened. In the same manner, the axle and mounts of the front fork were strengthened with an under-bracket that has a height of 40mm (versus 25mm before) while at the same time the wall thickness of the front fork inner tubes could be reduced. Also the swingarm, with the 'upside down truss layout' derived from the M1, is completely new with a 30% higher torsional rigidity while at the same time the lateral rigidity could be reduced slightly.

All these things combined create a greater responsiveness of the bike with a better feeling and feedback for the rider and a better traction out of corners.

More sporty setup:

The new R1 is tuned even more towards sporty riding, following Yamaha's 'no compromise' philosophy: The rear suspension has a sportier base setting, and also a more progressive linkage rate and a 2-way (low and high speed) compression damping adjustment. Also the front suspension is set up more sporty with a higher spring rate. It also has a completely new high-performance design, with a larger piston diameter to give a very precise and stable hydraulic damping. The piston rod is now of a new, light-weight aluminium design. The front brakes are equipped with new 6-piston (radial mounted) callipers, to make fuller use of the disc at its perimeter. This creates an outstanding brake performance, while at the same time the disc diameter could be reduced from 320 to 310mm for lighter rotating mass and better agility.

Engine: high excitement

The engine setup is modified in important ways too. "The over-rev area is much more exciting, and feels more powerful" says Oliver Grill, Product Planning manager for motorcycles at Yamaha Europe. "The bike has 180 horsepower now. It would be no problem from a technical point of view to reach a much higher figure, but that would give no benefit to go faster in reality. Our target was to be fastest on the track, so the controllability of the high level of power was crucial. Lap-time is usually gained not on the straight but in corners, so you need the best control of acceleration at any moment of cornering, the best stability under braking, etcetera."

Latest engine technologies

To control the huge power of this engine, Yamaha is pushing the technological development forward in many ways:

- YCCT: Yamaha Chip Controlled Throttle.

This technology, directly derived from Valentino Rossi's championship-winning M1 race bike, 'translates' the throttle opening by the rider, combined with information from temperature, speed, lean angle etcetera, into the correct throttle opening in the intake duct. This helps to achieve a smoother torque character and a higher level of rider-machine unity. It also simplifies the air intake passage because there is no need anymore for sub-throttle or secondary throttle systems.

- The compression ratio is increased from 12.4 to 12.7:1.

New, 4-valve cylinder heads were developed with redesigned combustion chambers and lightweight titanium intake valves which enable high valve lift. The bike now delivers 180 PS @ 12.500 rpm, and this is without the forced air induction effect that pressurizes the airbox at higher speeds!

- YCCI: Yamaha Chip Controlled Intake.

This system adjusts the length of the air intake funnels with an electronic control, depending on rpm and throttle opening.

- Normallly the length of the intake funnel is a compromise. A long funnel is best for torque at low and mid rpm, and a short funnel is best for high rpm and maximum top power.

The YCCI system makes it possible to use the high-rpm oriented system with the short funnel layout, while keeping the higher torque characteristics of the long funnel at low and mid rpm

- One of our testriders summarized it like this: "It gives a lot of riding sensation and performance, without sacrificing midrange."

- The new engine now features a slipper clutch: a typical race-spec feature to help to prevent slipping of the rear wheel due to the back-torque of the engine, for example while approaching corners during hard braking. The system is basically similar to the one used on the top-spec 2006 R1 SP model.

- The new R1 also features an optimised, full titanium exhaust system with dual EXUP, 3-way catalyser and a new elliptical shape muffler design.

On the road

Despite the amount of race-spec features, is the new R1 still usable on normal roads? Oliver responds: "We know that many customers will use the bike on public roads and of course we take care that the R1 will also perform in those conditions, with more than enough excitement factors such as the superior road-holding, the fantastic agility, the exciting engine, the best brakes. And last but not least, the bike has this great sound with an aggressive touch."

YZF-R1: State Of The Art Race Technology

A decade ago, the YZF-R1 set new standards in the world of supersport bikes. Ever since the R1 has become an icon and embodies Yamaha’s racing DNA with the spirit of competition in every component. In the last 10 years, the R1 has undergone 4 major model changes in 2000, 2002, 2004 and in 2007. Of course a lot of other improvements have been made almost every year during its lifecycle so far.

The new R1 is a complete redesign with new engine and chassis. The direction of development was clearly focused on more sporty performance in general. The knowledge gained in GP racing with Valentino Rossi’s YZF-M1 has been implemented into the 2007 YZF-R1. New engine

The new R1, with an even more super square bore & stroke of 77 x 53,6 mm, benefits from an entire new cylinder head where four valves-per-cylinder combustion chambers were adopted. This has allowed more upright inlet and exhaust valves positioning, and thus helping boost top end power to 180 PS/12,500rpm. Even then, an extra 9hp is available, thanks to the effect of the redesigned pressurized air intake system that comes into its own at higher speeds.

Titanium inlet valves have been adopted, with all the valves in the engine now operated by lightweight VX Alloy valve springs. More racing technology introduced on the 2007 R1 for the benefit of street riders comes from the use of a similar slipper clutch found on the 2006 YZF-R1SP.